Processes

Click to configure > Processes

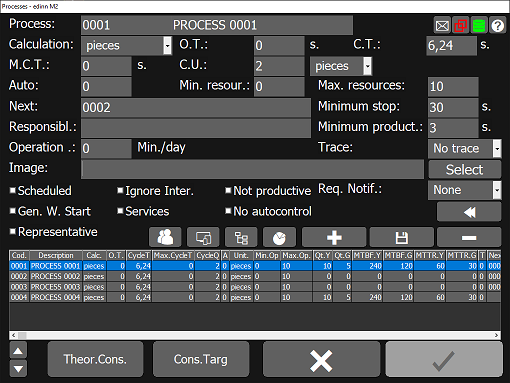

In the lower part: you will see a grid with the processes already configured, on which you can perform operations on the grid such as Insert, Save or Delete.

In the upper part: you will see the configuration of each record, where you can configure the parameters of a new insertion or edition.

CONFIGURATION PARAMETERS:

- Process: code and description of the process. For example: GE, Electrogen group.

- Calculation: how to calculate the units produced by the process. The available options can be configured at the Calculation types configuration.

- O.T. (Operator Time): time in seconds of work of the resource (person) per cycle time.

- C.T. (Cycle Time): time in seconds per cycle of production. Please see Maximum speed.

- M.C.T. (Maximum Cycle Time): if different than 0,

- It will be the default cycle time for orders created with the Integration Module (ISA-95).

- There will be a special behaviour for statuses marked as Req. result.

- The monitor will adjust Cycle Time and Cycle Units based on this parameter.

- See later as it will generate certain special behaviours in combination with operation time.

- C.U. (Cycle Units): number of units expected per cycle of production. Please see Maximum speed.

- Unit selector: the unit identificator of what the process produces.

- Auto: indicates the number of units of results with a maintained speed for the system to automatically update the maximum speed of the process. Automatic update of maximum speed is disconnected if this value is left to 0. This options is used when the cycle time is unknown.

- Min. Opers / Max. Opers: minimum and maximum number of working persons that can work at the process at a certain moment.

- Minimum stop: minimum stop time in seconds in order to be registered as failure (FAI). Stops with less time will be registered as microstops if the field microstops has been informed below.

- Next: processes that follow the actual process. Please see difference between production lines and areas.

- Responsible: person in charge of the machine in case of notifications.

- Production minimum: minimum time in seconds that a process must be working to be shown as working. This parameter is also used to determine the time that a piece needs to go from a counter of totals to a later counter of goods.

- Microstops: status that will be automatically used to automatically justify microstops.

NOTE: detecting microstops requires that the server checks status of counters more frequently than the "minimum stop time". In general, the more frequently the server check the status of counters, the more precision you have in detecting microstops. Please contact your technical support to validate this.

- Trace: to indicate, if signals are monitored, and the information is sent to the terminals (Devices) or is left alone in the server (Central).

- URL: document or application that will be opened when the user clicks on the

that appears after having clicked on the process, on the main window. Please see how to configure URLs. URLs can be selected from

that appears after having clicked on the process, on the main window. Please see how to configure URLs. URLs can be selected from  and its syntax can be cheched from the button

and its syntax can be cheched from the button  .

. - Lock: indicates after how many minutes status and result registers will be blocked for users without supervisor permission. This allows to force justifications before a certain time. This parameter will also allow to send notifications when statuses are not justified.

- Monitor: select the type of monitoring:

- Manual: the process is not monitored automatically and therefore buttons are shown for the working user to indicate manually when a good or defective piece is produced.

- Auto. Prod.: production is automatically monitored. The rest (rework and scrap) should be indicated manually.

- Auto. Scra.: scrap is automatically monitored. The rest (production and rework) should be indicated manually.

- Auto. Prod. Scr.: production and scrap are automatically monitored. The rest (rework) should be indicated manually.

- Auto. Rewo.: rework is automatically monitored. The rest (production and scrap) should be indicated manually.

- Auto. Prod. Rewo.: production and rework are automatically monitored. The rest (scrap) should be indicated manually.

- Auto. Scra. Rewo.: scrap and rework are automatically monitored. The rest (production) should be indicated manually.

- Full auto: all types of results are automatically monitored.

- Allow conf.: allows the user to configure the process and to add more statuses and more results.

- Notify: if selected, the system will notify by email (1) when the selected ratio (OEE, Availability, Speed or Quality) is below the yellow target, in any of the defined periods. Please see Notification priorities. You can also select Scheduling and then the notification will be sent when finishing or pre-finishing an order and having produced a certain % more or less than the target quantity. You can indicate this excess or default % in the field Deviation, which will be activated only in this case.

- Fields: to configure default values for the fields of this process. Fields allow the user to adapt the platform to a specific industry. For more information, please see: Fields Configuration.

- Ratios configuration (OEE, PE, OCE): green and yellow targets for the OEE and PE (is the same as the OEE but without considering idle statuses) and OCE ratios for the processes. By clicking any of these fields, more targets will appear: please see Ratios configuration.

shows more options:

shows more options:

- Operation time: for Work Management, type the seconds per day that the process should work in labour days. It is useful to calculate availability as the percentage of time that the process was working comparing with this number, independently of the time schedule that the process followed. It also affects the speed ratio, which turns into the percentage of the time that the process met the due dates of the orders it performed. Therefore, if different than 0, it will affect how the availability and speed ratios are calculated and:

- Availability: you should schedule statuses to define, for this process and every moment, which days are of classes holiday, vacation and weekend. All the rest of the time will be considered as labour. For each labour day, the system will expect the process to have been working the time indicated here. The percentage of availability will be calculated based on the real production time versus what is indicated here.

- Speed: you should use the scheduling module. It will be calculated according to the orders performed by the process in the period, comparing the production time with the delayed time with respect to the due date and time limit of the order. If there is no delay, then will compare the actual dedicated time to the task or work order versus the estimated time for it. Therefore, for a process which is a person to maintain high the speed ratio, he/she should assure that the limit date of the tasks or work orders is on the future before starting them, that he/she finishes them before the limit date and that he/she works in them less time than their expected duration.

- If, in addition, the Maximum Cycle Time is different than 0, and the Scheduling Module is activated, then the monitor will calculate the time when the process should generate results as what happens first between the due date of the current working order and the date resulting by adding the Maximum Cycle Time to the last date when results where generated, considering only labour periods.

- The process will automatically pass to a stopped status if it is without an active work order for more than the time of Stop Minimum and the moment of the next result is not calculated based on fields (for example with DateAsRef).

- Image: select the image for the process.

NOTE: If you upload a new version of a file with the same name, and it does not refresh to the new version, it might be because this function uses the web server and some web servers provide images from cache. In that case, please upload the same image with a different name of file.

- Scheduled: if marked the process is restricted to follow the orders scheduled for it, and that can be viewed at the view schedule window.

- Ignore inter.: marks the process as to be ignored when transferring from and to information to another system, like ERPs. Please see integration with other systems.

- Req. Notif.: this selector forces the user to indicate quantities when closing an order in the selected items.

- Gen W. Start: this mark indicates to the system to automatically generate a new status to indicate that a new work has started, every time a new result with 0 quantity is inserted, if at the status configuration the option Work start has been marked for one, and no more than one, status.

- Services: indicates that the process is dedicated to attend services. This mark will, for example, show the working time of these processes as services in the FTE report.

- Not productive: indicates that the process is not productive and therefore:

- The system will not calculate OEE, OCE, MTBF and other ratios for this process.

- The system will not show it in certain views and reports.

- The monitor service will ignore all items associated with this process.

- Its calendar will not be updated.

- Alerts about this process will not be notified.

- No failure predictions will be made for this process.

- It will not be shown in the drop down lists to manage work orders.

- It will be ignored by the automatic production scheduler.

- No autocontrol: disactivates all automatic generation of autocontrol tasks.

: to select the resources to authorize in the selected process.

: to select the resources to authorize in the selected process. : to select the devices with access to the selected process.

: to select the devices with access to the selected process. : to select the areas to assign to the selected process.

: to select the areas to assign to the selected process. : to create a dashboard for the selected process, using a template. These dashboards, when associated to devices, can be used as a screen saver in the configuration of devices.

: to create a dashboard for the selected process, using a template. These dashboards, when associated to devices, can be used as a screen saver in the configuration of devices.

- Theor. cons.: to configure the theoretical consumptions for the selected process. Please see: Theoretical Consumption.

- Cons. Target: to configure the targets of consumptions for the selected process. Please see: Consumption Targets.

WARNING: Some process configuration parameters influence the way in which the Monitor Service captures the information automatically from the process and also the behaviour of Central Services. Therefore, if we change certain parameters, it is recommended to advise the system technical support to optionally adjust the server and restart the monitoring systems.