Configure Times

In this document we will explain the necessary configuration to set up the cycle time, what is speed loss, what is micro stop and what is a stop.

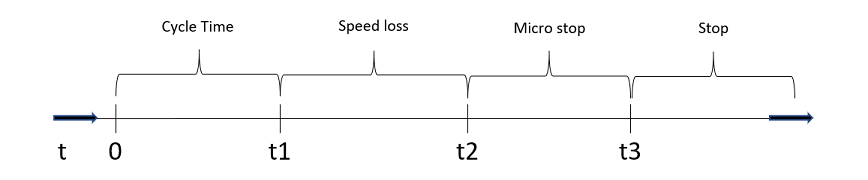

For a better comprehension, please see the graphic below:

Where:

- Cycle time (t1): it is configured by indicating every how much time we obtain how many results, in processes configuration and PSR relation configuration. The system will take the data configured in PER relations. Configuration in Processes is only for when new relations with new results are being created, that the system takes this data as default. It is important to note that you can also:

- Configure this data in an order and the system will take it prior to PER relations.

- Make this times depending on calculations of fields, which can be automatic or manually inserted by users.

- Threshold (t2): it is configured as a percentage in the server console, monitor tab, for every total production counter. It is the percentage of speed that we accept to consider that the process is in production, although at a lower speed. In other words, if the speed of the process is lower than the nominal speed, stablished by the combination of units and cycle time, multiplied by this percentage, then the process will be considered as not in production.

- Micro stop (t3): it is configured in seconds in the field Stop Minimum in processes configuration. It is important to notice that you should also indicate in processes configuration the status that the system will take as a micro stop.

- Stop: every stop which exceeds the t3 time, will be considered as a stop (FAI, from failure) and the system will search for an automatic or manual justification.

Therefore, every cycle time which is:

- Longer than t1 and shorter than t2: will be considered inside the speed loss type.

- Longer than t2 and shorter than t3: will be shown as a micro stop and considered inside the availability loss type.

- Longer than t3: will be shown as a stop and considered inside the availability loss type.

Example:

Let us suppose that for a certain process, status and result, we have the best cycle time (also known as nominal capacity) of 60 seconds for 1 piece, and we want:

- Until 90 seconds, the system should consider a speed loss.

- Every stop which is less than 3 minutes, should be considered as a micro stop.

The values that we should configure for this example are:

- t1: CycleQ = 1 (piece) and CycleT = 60 (seconds).

- t2: As we want to admit 90 segundos, the threshold should be 60/90 = 0,6666 = 66,66%.

- t3: As we want that every stop which is less than 3 minutes to be auto justified as a micro stop, then we will type 180 seconds.