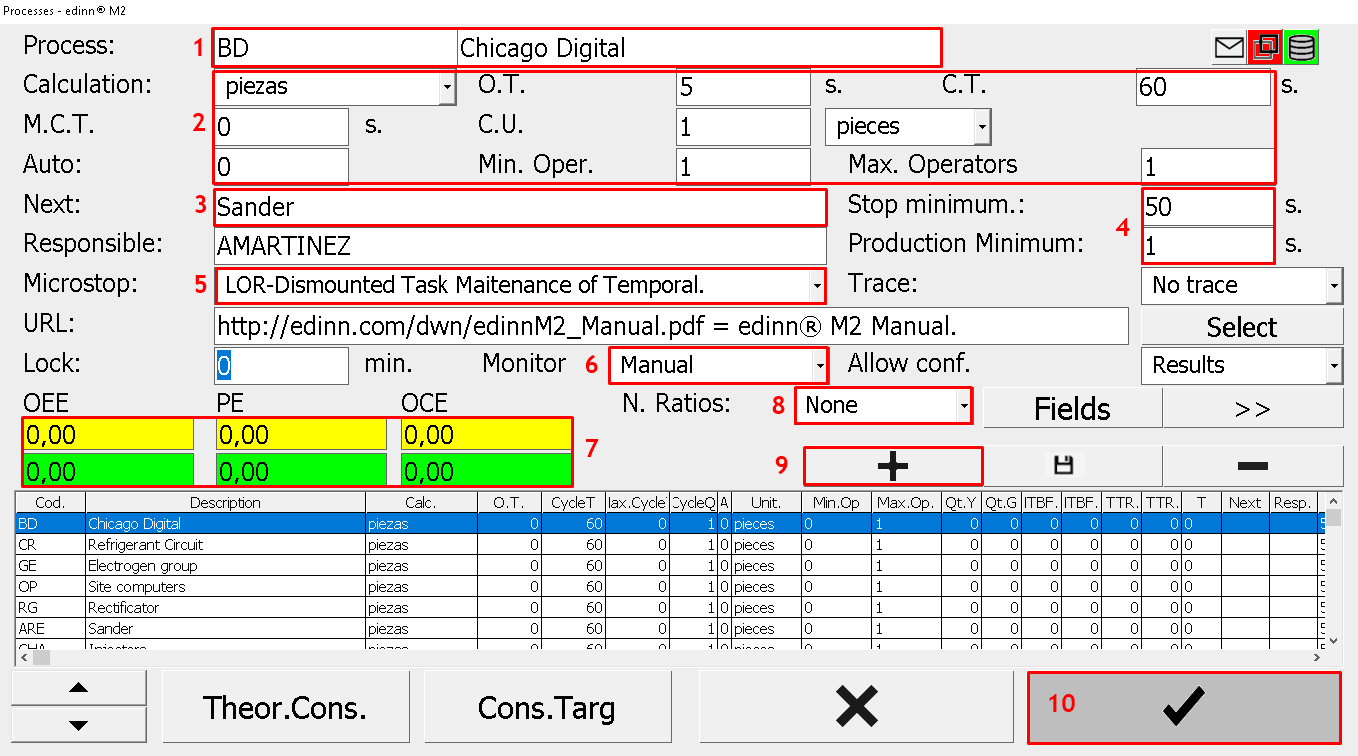

How to configure a process step by step

To create and configure the processes of a plant, complete the following minimum required configuration in [Click to configure] select [Processes]. To configure the rest of the fields, access Configuration processes.

Step 1. Configuration for each process

- Process: write the name (e.g: Pulisher Group A) and identifier (e.g: A901) of the process to be configured.

NOTE: If new processes or areas are created, check that they are visible to devices or users.

- Times & resources: configure each field (Calculation, O.T, C.T, M.C.T, C.U, Auto, Min. Oper, Max. Oper.) fundamental for calculating the process availability ratio.

- Next: for linear layouts, determine what the next process is. Utility: if a stop occurs in Machine 1, if it affects Machine 2, the Machine 2 will suffer a "Dependency" (which does not affect the OEE calculation of this) instead of a "Stop".

- Stop & production minimum: define the minimum time for the monitor to consider a production (generally, the time used to manufacture two pieces) and the minimum time from which a stop will not be considered micro-stop and, therefore, it will have to be justified by the user.

- Microstop: in case of detecting a micro-stop in the production, indicate with what status it will be qualified.

- Monitor: indicate if the quality issues (scrap, rework...) are going to be automatically or manually monitorized.

- N. Ratios: selecte if you want the system to notify by email when the selected ratio (OEE, Availability, Speed or Quality) is below the yellow target.

- (IMPORTANT) Ratios: configure the green and yellow objectives for each of the process variables, for more information, see Configuration Ratios.

Step 2. Save changes

- Press

to insert the process configuration into the table. Repeat this action for each process of the plant.

to insert the process configuration into the table. Repeat this action for each process of the plant. - Press

to make all the changes effective.

to make all the changes effective.

NOTE: the commonly configured fields have been presented, to know the definition of the other fields, please go to: Configuration Process.