What is OEE?

The international standard ratio to measure Production Efficiency is called OEE (Overall Equipment Effectiveness).

NOTE: With regard to Work Management, for information on how the availability and speed ratios are calculated in a way more appropriate for processes which are persons, please view 'operation time' in processes configuration.

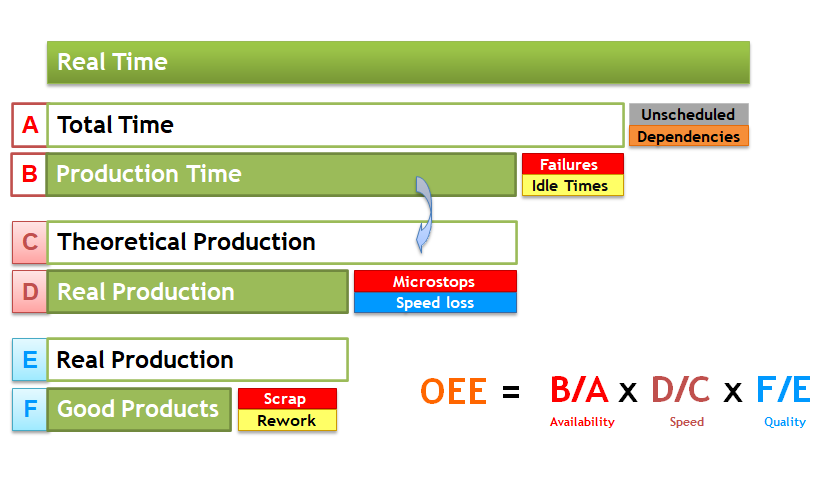

OEE CALCULATION:

The advantage of the OEE, compared to other ratios, is that it measures, in one ratio, all fundamental parameters regarding productive losses: Availability, Speed and Quality.

These three ratios compose the OEE and, by analyzing them, it is possible to know what losses, until 100%, are caused by:

AVAILABILITY CALCULATION:

Availability = B / A

Where:

- A. Available time = total time that the process could have been producing = [natural time] - [not scheduled time to produce] (such as holidays, lunch, programmed maintenance tasks, weekends...).

- B. Running time = time the process has being producing = [available time] - [failures and idle times]

SPEED CALCULATION:

Speed = D/ C

Where:

- C. Theoretical production = number of products that could have been produced = [running time] * [nominal production speed].

- D. Real production = number of products produced = [theoretical production] - [microstops and speed loss]

QUALITY CALCULATION:

Quality = F / E

Where:

- E. Real production = total number of results produced.

- F. Good production = total number of good results produced.