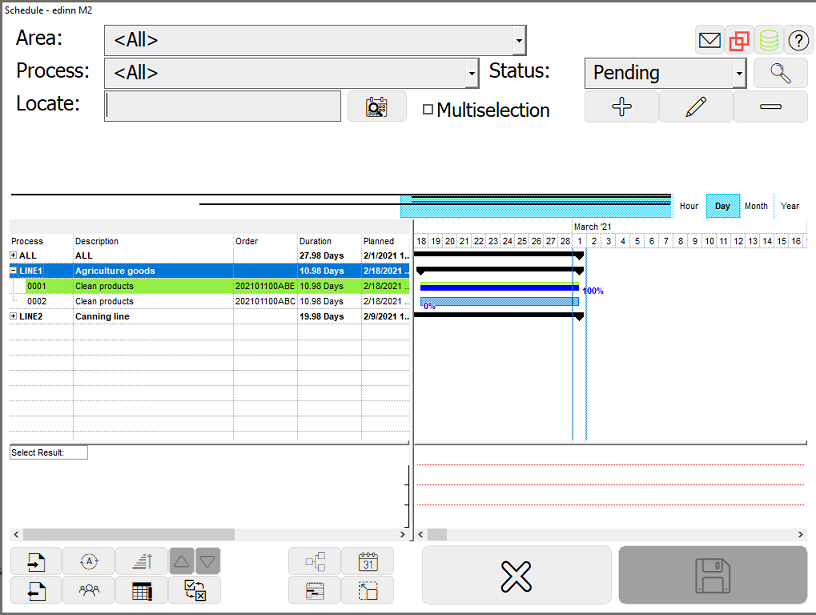

Edit schedule

Main Window > Schedule > Edit

Detail is as follows:

- Area and Process: selects the area and process for which we want to see the scheduled orders.

NOTE: Archived areas will not appear in the selector. To learn more about archiving areas see area configuration.

- Status: allows to select the status to search.

- Search: refreshes the data grid.

- Locate: locates in the table or gantt.

Buttons:

imports new work orders from the clipboard, from project files (.xml, .bc3) or Excel (.csv).

imports new work orders from the clipboard, from project files (.xml, .bc3) or Excel (.csv).

Note regarding import from CSV

The mandatory fields (ordered according to the Excel columns) are: Area, Proc., W.Order, Qt, Targ., Scheduled, Limit, Setup, C.T*, C.U*, Teardown, Res., Calc, Rec.

*In C.T and C.U if the entered value is 0 , it will inherit the values configured in PSR Relations.

In the "Predecessors" and "Relation" fields, enter the working orders codes (separated by commas) with which you want to relate the working order and the relation between them, respectively.

The relations types are:

0- Finish-Finish

1- Finish-Start

2- Start-Finish

3- Start-Start

4- None

exports work orders to Excel (.csv)

exports work orders to Excel (.csv) automatically schedules the selected orders. First performs an adjustment based on their dependencies and second, only for the tasks/orders in pre-scheduled status, an advanced schedule. Please consider also that the calendar for the availability of the processes is indicated by scheduling statuses. For this, please review the notes and warnings of statuses configuration.

automatically schedules the selected orders. First performs an adjustment based on their dependencies and second, only for the tasks/orders in pre-scheduled status, an advanced schedule. Please consider also that the calendar for the availability of the processes is indicated by scheduling statuses. For this, please review the notes and warnings of statuses configuration.

Note regarding priority

The automatic scheduler will prioritize plans which:

1st) Have less delay, considering the scheduled date and times with respect to their limit date and time.

2nd) Are finished sooner, with respect to the current moment.

3rd) Have a lower WBS field, according to their alphanumeric order. Therefore, you can use the WBS field to prioritize between clients or other criteria.

For example, if you have clients type A, B, C, etc.: you could the A in the WBS field of those orders of client A, and so forth, and for production plans where the 1st and 2nd previous criteria are equal, then the scheduler will prioritize plans of client A versus B.

changes the priority (WBS) of the selected orders.

changes the priority (WBS) of the selected orders. changes the priority (WBS) of one order based on its order in the table grid.

changes the priority (WBS) of one order based on its order in the table grid.

Note: This function can be used in table view and only if the table grid is ordered according to the "priority" column.

assigns resources. For more information, please see: "Assign personnel and team window".

assigns resources. For more information, please see: "Assign personnel and team window". shows a table with the issues of the orders.

shows a table with the issues of the orders. changes the status of the selected orders.

changes the status of the selected orders. shows the processes in a tree structure for a faster access.

shows the processes in a tree structure for a faster access. shows the calendar calculated by the system based on the statuses configuration or the statuses which really occured.

shows the calendar calculated by the system based on the statuses configuration or the statuses which really occured. shows the schedule in a gantt chart or

shows the schedule in a gantt chart or  table grid.

table grid. maximizes the table or the gantt.

maximizes the table or the gantt.- Press

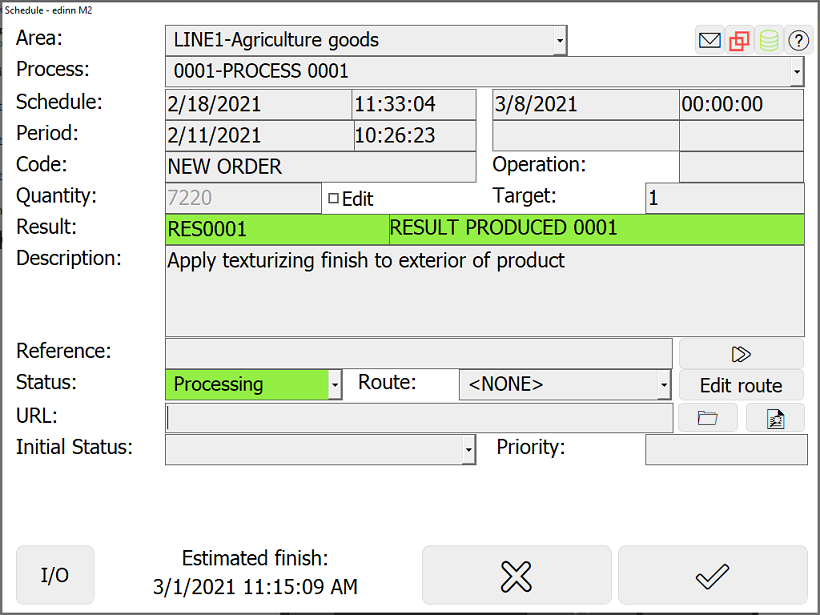

to create a new order:

to create a new order:

- Area: select the area to which the order will be assigned.

- Process: optionally, select the process, inside the selected area, which will perform the task/order.

Note: until an order / task is assigned to a process, there will not be any alarms about delays in the win32 terminal.

- Schedule: date and time to start and to end (limit) of the order.

- Period: real period in which the order has started and finished.

- Order: id of the order. By means of an option within the server configuration, this field can be automatically dumped to the order field of the result when the scheduled order is started.

- Operation: id of the step inside the ordern

- Quantity: results produced until now.

- Edit: indicates if the QT field should be updated by clicking on accept in this window. If not, it will not be modified. This is to avoid, if the order is being processed, that when changing something in the order, we mistakenly change the produced quantity until now.

- Target: quantity that should be produced.

- Result: result code to produce.

- Description and Reference: free texts.

- Status of the order:

- Prescheduled: the order (not the work indicated by the order) is being prepared.

- Scheduled: scheduled to be produced.

- Processing: being processed.

- Paused: paused.

- Prefinished: finished, but waiting for approval to pass to finished.

- Finished: finished.

- Canceled: canceled or will not be started or contined.

- Status (time usage): used to read the corresponding fields of the process-status-result relation. It can be configured to be requested to the user. The list of statuses comes from the PSR relation.

- Route: the following processes through which the result will go, or if the user tries to assign the order. Please see routes configuration. You can choose a route from the list of templates of routes and it will be copied to as the route of this order. You can then change the route by using the button Route, explained below.

- Edit Route: to configure a specific route for the order.

Note regarding the routes: When saving the changes of this order, you will be asked to automatically generate the operations of the route. If answered yes, the system will generate an order with different operation code, according to the route, for each process indicated in the route.

If inside a route, in the step of an operation, a process has been selected, then the automatic scheduler (see buttons above) will take as possible processes all the processes which have that same result as PSR Relation.

If inside a route, in the step of an operation, an area has been selected, then:

1) For the creation of the operations (steps of the route), the system will select the first process of that area which is not in an unscheduled status.

2) The automatic scheduler (see buttons above) will take as possible processes for that operation only those which belong to that particular area and which have that result as PSR Relation.

- URL: document or application that will be opened when the user clicks on the

that appears after having clicked on the order, on the view schedule window. Please see how to configure URLs. URLs can be selected from

that appears after having clicked on the order, on the view schedule window. Please see how to configure URLs. URLs can be selected from  and its syntax can be cheched from the button

and its syntax can be cheched from the button  .

. - Initial status: the process will automatically enter in this status when the order will be initiated.

- Priority (WBS): value to prioritize the orders.

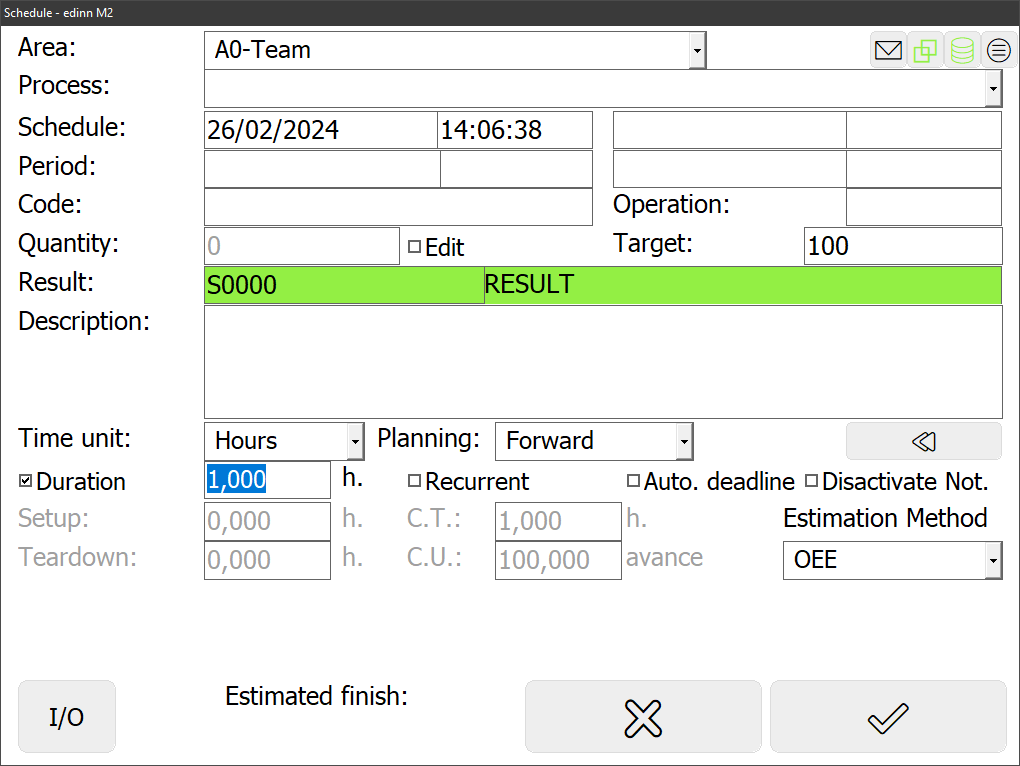

- Time unit: Indicates the unit of the time fields on this form from the following: seconds, minutes, hours, and days.

- Planning: if this order should be automatically scheduled forward of backward.

- Recurrent: indicates if the order is recurring. If marked, when starting the order, if the quantity if greater than the target, then it will understand that it must restart the order and will put the quantity to 0. All recurrent tasks have also marked the Auto. deadline mark.

- Auto. deadline: indicates if deadline date must be calculated automatically. If marked, deadline date will be calculated continuously, based on the times of the order, while the order in in a pending status and, as the last time, when the order is started.

- Deactivate notif.: prevents production to be notified on this order. This is useful when there are more than one operation and you want the initial operations to be only to report inputs and outputs, and only in the last operation report results. In this example we would mark this in all operations except in the last one.

- Time parameters. Any change in these fields will automatically update the limit date and time seen above:

- Duration: Indicates the total duration of the order, if checked, the rest of the time parameters will adapt to the time indicated in this box. If not checked, this box will be the one that will adapt to the values entered in the rest.

- Setup: expected time in seconds to prepare the order.

- C.T. (Cycle Time): time in seconds per cycle of production. Please see Maximum speed.

- C.U. (Cycle Units): number of units expected per cycle of production. Please see Maximum speed.

- Teardown: expected time in seconds to dismantle the order.

- Estimation method: Indicates the criteria to establish the estimated time. It can be by OEE or by nominal capacity.

- I/O button: for configuration of the expected inputs and outputs of the order. Please see inputs and outputs window.