Process-Status-Result (PSR)

Click to configure > PSR relations

Process-Status-Results relations is the configuration to relate results with statuses and with processes. The results and statuses that have not been related with processes, cannot be used by users nor the system will not take them into account in certain functionalities.

In this window, for each status and result, it is possible to assign different or the same characteristics of the status configuration and the results configuration. This is useful when it is needed to have certain characteristics (the ones present on this window) specific for certain processes, statuses and results. For more information please see particularization through relations.

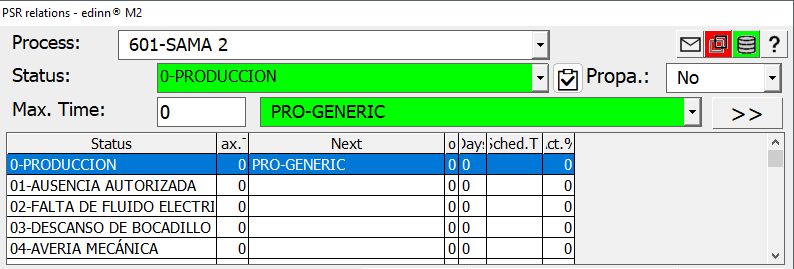

In the upper part: you will see the configuration for the statuses, with a grid with the relations between Processes and Statuses already configured

In the lower part: you will see the configuration for the results, with a grid with the relations between Processes, Statuses and Results already configured

Above each grid you will see the configuration parameters, with which you can perform operations on the database such as Insert, Save or Delete.

Cons. button: allows configuration of specific consumptions parameters for this process, status and results.

CONFIGURATION PARAMETERS FOR STATUS (and a specific process):

- Process: for which the relation is established.

- Status: for which the relation is established.

- Check button

: to add/remove relations between one status and multiple processes.

: to add/remove relations between one status and multiple processes. - Propagate: if the status will be automatically propagated to processes that are later in the area. Please see difference between production lines and areas.

- Max. Time: maximum time in minutes that the selected process can be in this status. In the field on the right you can specify the next status that will begin after the closing of the initial status. Additionally, if you try to justify an undefined status (FAI) to this status, the system will only accept the maximum justified minutes, the rest will be also required to be justified. Please see configuration of Statuses for more information about this field.

For example: you can set the maximum time of a change of a produt to be 60 minutes, once surpassed, the system will automatically close this status.

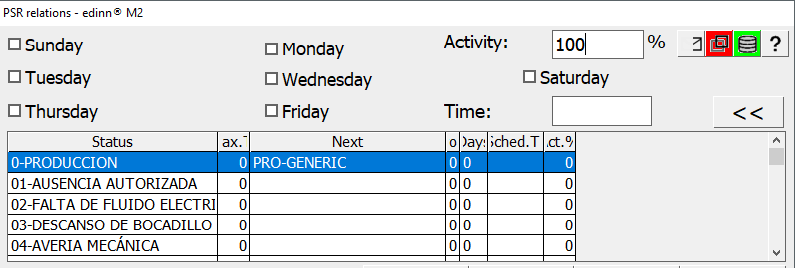

shows more options:

shows more options:

- Schedule: status can be automatically scheduled by days of the week and time. This allows, for example, to close days or weeks with END OF PRODUCTION and start them up when needed.

- Time: time at which the status will automatically be inserted.

CONFIGURATION PARAMETERS FOR RESULTS (and a specific process):

NOTE: you can only view or manage results having previously selected (in the table above) a production status and clicked the button with the magnifying glass icon.

- Result: code and description of the result related to process and status.

- Disallow conf.: does not allows the user to configure the process and to add more statuses and more results.

- Operation time: type the seconds per day that the process should work in labour days. For more information please view the help of the processes configuration.

- Op.: maximum number of working users that can be working on this Process, Status and Result.

- Activity: percentage of activity that is required for the working user. This is a requirement configuration for the activity report. For example: if we introduce a value of 100%, will mean that the resource (person) must achieve 100% of OEE in this process, when in this status and producing this result.

- Date and time: date and time when this PSR relation starts applying. This is useful to change important parameters, like Cycle Time and Cycle Unit, without affecting historical data.

shows more options:

shows more options:- Propagate: if marked, the result change in this process and status will be cascade propagated to the related processes.

- Fields: to configure new and customized fields for the PSR relations, This allows the system to adjust to any sector, as the organization can create its own information fields.. For more information, please see: Fields Configuration.

- Drop down combo of calculation types: here you can indicate the Calculation type which will be used to calculate the nominal speed (Cycle Units / Cycle Time). This is useful for the system to automatically supervise the results and when they are generated, since the working user can be required to indicate the estimated time and quantity of results.

WARNING: Please note that this field is not the same as the Calculation of the Process configuration. The one in the process configuration is to calculate production, and this is to calculate nominal speed. Leave this field blank if you do not need to automatically calculate the nominal speed (Cycle Units / Cycle Time).

- O.T. (Operator Time): time in seconds of work of the resource (person) per cycle time.

- C.T. (Cycle Time): seconds for each cycle time. Please see Maximum speed.

WARNING: Please verify that the Cycle Time is equal or greater than the "Check counters every" of the edinn Server Console, Monitor, Common Tab.

- C.U. (Cycle Units): number of units of results expected per cycle of production. Please see Maximum speed.

- Auto: indicates the number of units of results with a maintained speed for the system to automatically update the maximum speed of the process. Automatic update of maximum speed is disconnected if this value is left to 0.

- Operation time: type the seconds per day that the process should work in labour days. It is useful to calculate availability as the percentage of time that the process was working comparing with this number, independently of the time schedule that the process followed. It also affects the speed ratio, which turns into the percentage of the time that the process met the due dates of the orders it performed. Therefore, if different than 0, it will affect how the availability and speed ratios are calculated.

WARNING: This field will take by default the same value as the homonym field in process configuration and has the same implications, but it allows setting different values for different dates or results.

- Copy: there are three possibilities:

- If olny the process is selected, it will copy state and results from the selected process.

- If a status is selected, it will copy the related results of the selected satus.

- If a result is selected, it will copy fields and consumptions of the selected result.

- Paste: paste the data copied with the previous button.