Customization of data

The data shown in the report Analysis, Panel, Data can be configured in the Configure Devices window. To do so:

- Click on the

button from the Main Window of the Terminal.

button from the Main Window of the Terminal. - Select Devices in the CLICK TO CONFIGURE dropdown.

- In the following window, choose the device whose data field you want to configure.

- Modify the field Data Type. This field shows 2 options:

- Standard: it is the default configuration:

ProdGood;Good (units)

ProdTotal;Total (units)

TimeProdMin;Productive (minutes)

TimeNotProdMin;Not productive (minutes)

SpeedT;Nominal (un./min.)

Speed0;Average (un./min.) - Particular: allows that each device (terminal) shows specific information.

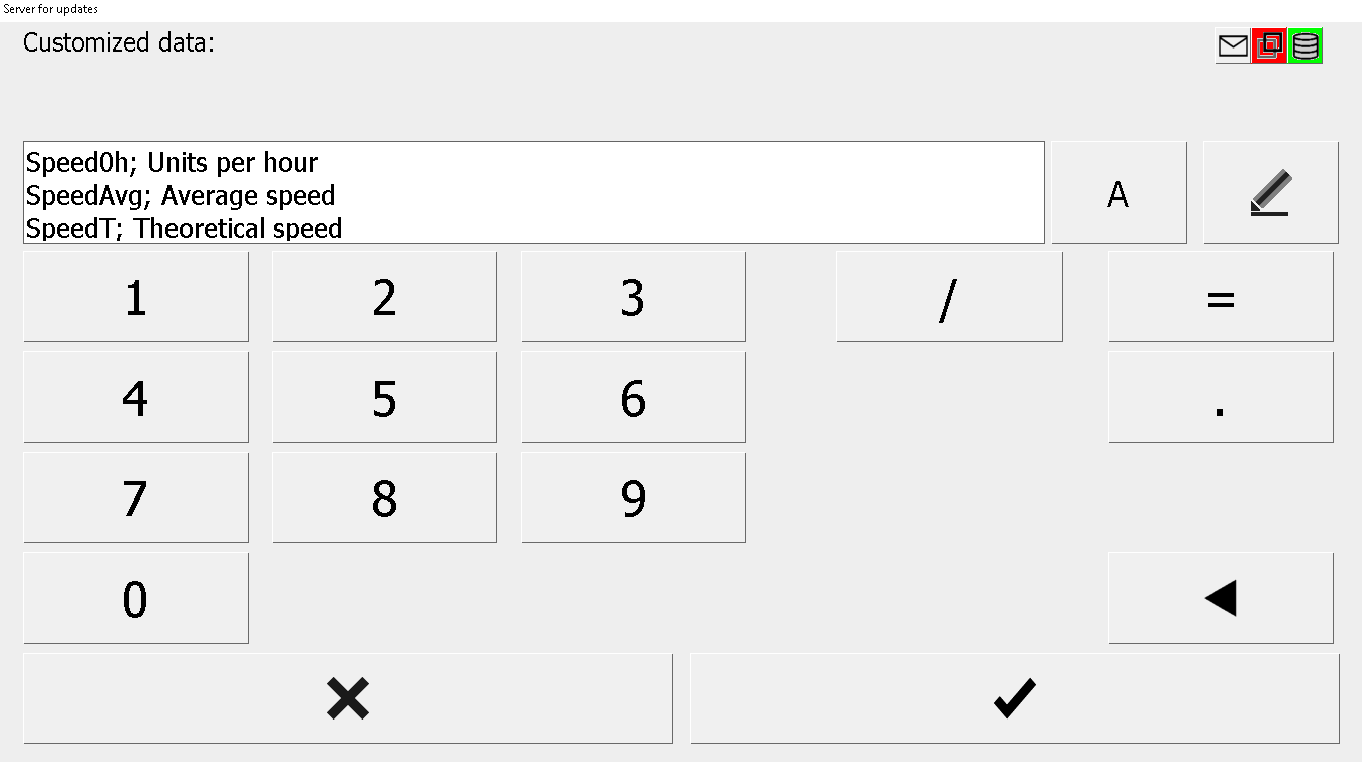

To configure the "Particular" option, use this syntax:

RESERVED TAG1; Free Text1

RESERVED TAG1; Free Text2

...

RESERVED TAG1; Free TextN

White lines can be introduced as separators. Type CTRL+ENTER to enter a new line.

When [0..2] is indicated, it means that the numbers 0, 1 and 2 can be appened to the tag. If omitted, it will consider all the period. If indicated, 0 means the period of the current result, 1 means the period of the previous result and 2 means the previous to the previous.

For example ProdTotal is the total production of the period, ProdTotal0 is the total production of the current result, ProdTotal1 is the total production of the previous result and ProdTotal2 is the total production of the previous of the previous result.

Available RESERVED TAGs, in alphabetical order, are:

- CommentWO: shows the comment of the current order.

- CPK: shows actual CPK for the selected measure.

- CycleQ: quantity produced that was read in the last monitoring cycle in units.

- CycleT: number of seconds needed to produce the CycleQ that were read in the last monitoring cycle.

- CycleQTheor: theoretical quantity to be produced in a cycle for a given moment, taking into account the active result and the work order.

- CycleTTheor: theoretical number of seconds of a cycle for a given moment, taking into account the active result and the work order.

- CycleTEquiv: shows the actual average cycle time, in seconds, to produce the number of cycle units configured in the nominal production capacity.

- DueDateWO: shows the due date of the current order.

- EstimationWO: shows the time that edinn has calculated that it will take to finalize the current order.

- MonitorItemValue[id]: shows the current value of a monitor signal.

NOTE: the MonitorItemValue[id] tag must indicate the identificator value of the monitor signal. Example: MonitorItemValue[15].

- MTBF: shows MTBF for the selected period in minutes.

- MTBFLastUpdate: shows date and time of last update of MTBF information

- MTBFQ: shows number of failures in the selected period.

- MTTR: shows MTTR for the selected period in minutes.

- OEE: OEE ratio of the current shift in percentage.

- OEEA: availability ratio of the OEE of the current shift in percentage.

- OEEE: speed ratio of the OEE of the current shift in percentage.

- OEEQ: quality ratio of the OEE of the current shift in percentage.

- OrderWO: shows the code current order.

- PriorityWO: shows the priority of the current order.

- Id_Prod: reference of the current result.

- Prod[0..2]: reference of result.

- ProdBad[0..2]: total bad production or scrap in units.

- ProdBadKgs[0..2]: total bad production or scrap in kilograms.

- ProdBadWO: shows the scrap quantity produce in the current order in units.

- ProdGood[0..2]:total good production in units.

- ProdGoodKgs[0..2]:total good production in kilograms.

- ProdGoodWO: shows the good quantity produce in the current order in units.

- ProdReworkWO: shows the rework quantity produce in the current order in units.

- ProdTheor[0..2]: total production in units that could have been produced.

- ProdTheorKgs[0..2]: total production in kilograms that could have been produced.

- ProdTheorN: total production in units that could have been produced, but calculated by multiplying production time by the current nominal speed of the proces.

- ProdTheorTotalWO: shows the theoretical production of the current order in units.

- ProdTotal[0..2]: total production in units.

- ProdTotalKgs[0..2]: total production in kilograms.

- ProdTotalWO: shows the production of the current order in units.

- QaActivity: is the activity of the process considering only the production of Qa variable. It is calculated as follows: (Total Production (Qa) - Scrap Production (Qa) - Rework Production (Qa)) / (Total time of Activity in hours). Where the total time of activity is the total time of all the statuses of the period, but multiplying their seconds by their activity percentage.

- QbActivity: is the activity of the process considering only the production of Qb variable. It is calculated as follows: (Total Production (Qb) - Scrap Production (Qb) - Rework Production (Qb)) / (Total time of Activity in hours). Where the total time of activity is the total time of all the statuses of the period, but multiplying their seconds by their activity percentage.

- QcActivity: is the activity of the process considering only the production of Qc variable. It is calculated as follows: (Total Production (Qc) - Scrap Production (Qc) - Rework Production (Qc)) / (Total time of Activity in hours). Where the total time of activity is the total time of all the statuses of the period, but multiplying their seconds by their activity percentage.

- QtActivity: is the activity of the process considering only the production of Qt variable. It is calculated as follows: (Total Production (Qt) - Scrap Production (Qt) - Rework Production (Qt)) / (Total time of Activity in hours). Where the total time of activity is the total time of all the statuses of the period, but multiplying their seconds by their activity percentage.

- QaQbActivity[factor]: is the activity of the process considering the value of the product of Qa and Qb variables. It is calculated as follows: (Total Production (Qa*Qb) - Scrap Production (Qa*Qb) - Rework Production (Qa*Qb)) / factor / (Total time of Activity in hours). Where “factor” is a user added value (equal or greater than 1) and “total time of activity” is the total time of all the statuses of the period, but multiplying their seconds by their activity percentage.

- QaQcActivity[factor]: is the activity of the process considering the value of the product of Qa and Qc variables. It is calculated as follows: (Total Production (Qa*Qc) - Scrap Production (Qa*Qc) - Rework Production (Qa*Qc)) / factor / (Total time of Activity in hours). Where “factor” is a user added value (equal or greater than 1) and “total time of activity” is the total time of all the statuses of the period, but multiplying their seconds by their activity percentage.

- QbQcActivity[factor]: is the activity of the process considering the value of the product of Qb and Qc variables. It is calculated as follows: (Total Production (Qb*Qc) - Scrap Production (Qb*Qc) - Rework Production (Qb*Qc)) / factor / (Total time of Activity in hours). Where “factor” is a user added value (equal or greater than 1) and “total time of activity” is the total time of all the statuses of the period, but multiplying their seconds by their activity percentage.

NOTE: the system calculates production based on, potentially, up to 3 variables: Qa, Qb and Qc; combined by the formula of the calculation type of the process.

- Speed0: average current production speed in units / minute.

- It is set to 0 if the machine stops.

- Calculates the average speed by taking the last 2 results records and dividing the total amount produced by the elapsed time.

- Speed0h: average current production speed in units / hour. Same behaviour than Speed0.

- SpeedAvgR: average current speed in units / minute.

- SpeedAvgRh: average current speed in units / hour.

NOTE: SpeedAvgR, SpeedAvgRh tags are calculate from the last 10 records of the counter.

- SpeedClass[id]: speed of a interval time, taking into account only the states of the specified class, in units / minute.

- SpeedClassh[id]: speed of a interval time, taking into account only the states of the specified class, in units / hour.

- SpeedWOClass[id]: average speed of the current working order taking into account only the statuses of the specified class, in units / minute.

- SpeedWOClassh[id]: average speed of the current working order taking into account only the statuses of the specified class, in units / hour.

NOTE: identification values for each class are:

Productive = 0

Setup = 1

Teardown = 2

Failure = 3

Result change = 4

Tool change = 5

Corrective Maintenance = 6

Ordering and Cleaning = 7

Quality test = 8

Internal dependency = 9

External dependency = 10

No workload = 11

Audit = 12

Training = 13

Vacation = 14

Weekend = 15

Holiday = 16

Predictive Maintenance = 17

Preventive Maintenance = 18

Any class = 255

NOTE: SpeedClass[id], SpeedClassh[id], SpeedWOClass[id], SpeedWOClassh[id] tags must indicate the identificator value of the class. Example: SpeedWOClass[4].

- SpeedR: current speed in units / minute.

- SpeedRh: current speed in units / hour.

- SpeedT: theoretical speed (Nominal Capacity) or maximum speed in units / minute.

- SpeedTh: theoretical speed (Nominal Capacity) or maximum speed in units / hour.

- SpeedGTh: the theoretical speed (Nominal Capacity) or maximum speed in units / minute for the green objective.

- SpeedYTh: the theoretical speed (Nominal Capacity) or maximum speed in units / minute for the yellow objective.

- SpeedT*S%: shows average speed, multiplying theoretical speed (Nominal Capacity) by the speed ratio of the OEE (%), in units / minute.

- SpeedT*S%h: shows average speed, multiplying theoretical speed (Nominal Capacity) by the speed ratio of the OEE (%), in units / hour.

- StartedWO: shows the start time of the current order.

- TimeMin: total interval time (minutes).

- TimeNotProdHr: non productive time (hours).

- TimeNotProdMin: non productive time (minutes).

- TimeNowMin: total time from the start of the interval until current moment (minutes).

- TimeProdHr: productive time (hours).

- TimeProdMin: productive time (minutes).

- TimeRelativeToShift: percentage of time elapsed with respect to the time of the current shift.

- TimeProdRelativeToShift: percentage of time in production elapsed with respect to the time of the current shift.

- TimeResMin[0..2]: productive time in minutes.

- TimeSetupWO: shows the setup time of the current order in seconds.

- TimeStatusWO[id]: shows the time spent in one state in the current order in seconds.

WARNING: You need to have a Scheduling Module license to obtain the data with termination in "WO".

- TimeStatus[id]: shows the time spent in one state in seconds.

NOTE: TimeStatusWO[id], TimeStatus[id] tags must indicate the status code. Example: TimeStatus[FAI].

- TimeTeardownWO: shows the Teardown time of the current order in seconds.

If you do not find the label you are looking for, please contact edinn's technical support.

- Once the changes have been done, save the changes by clicking

, then click

, then click  to confirm them.

to confirm them.

- Now, the data panel report should show the data specified by the new configuration.