How to configure a status step by step

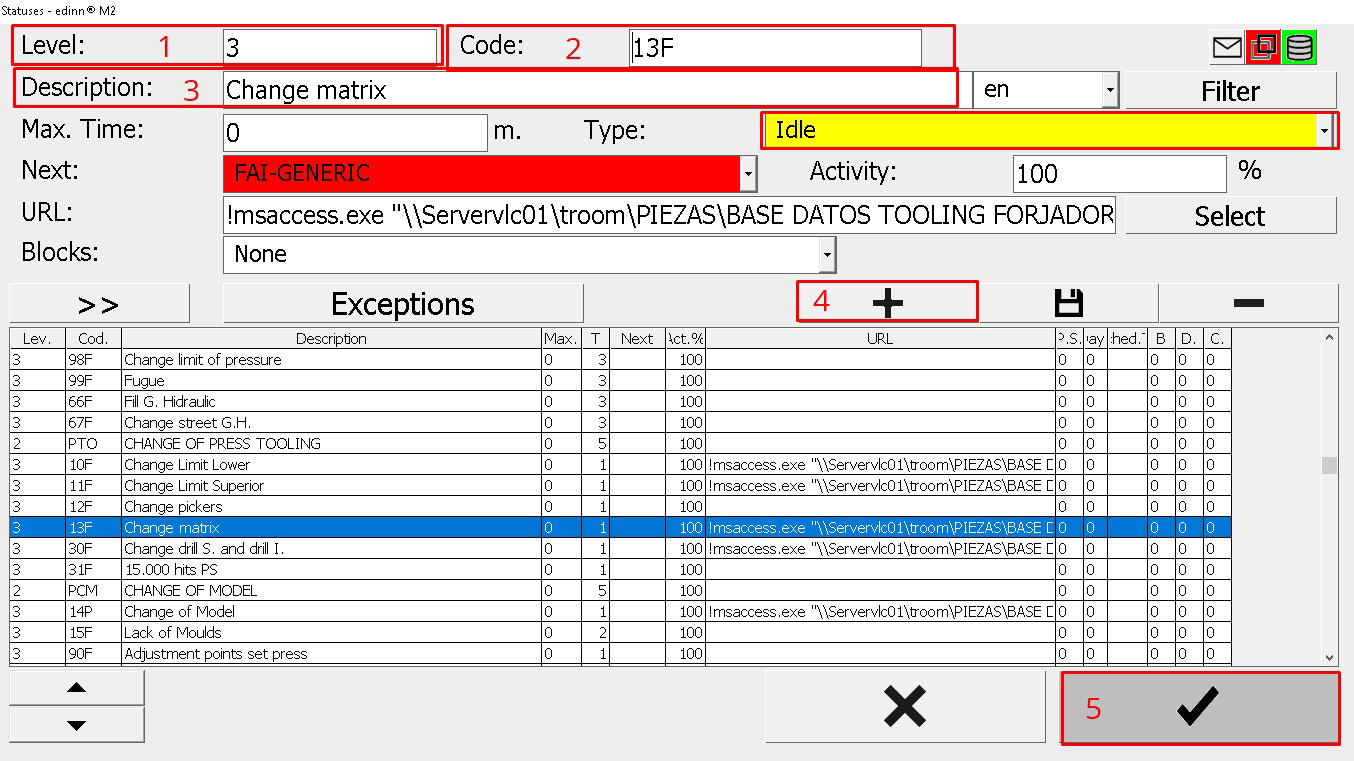

In [Click to configure] select [Statuses]. To create and configure results, complete the following configuration.

Step 1. List all the items

Lists all the statuses through which your machine can pass and its types, e.g:

- Production.

- Idle: process cleaning, product change, quality tests...

- Stops/Failure: motor failure, excessive pressure...

- Dependency: dependence on another process, lack of stock...

- Not scheduled: break, weekend...

- Title: agrupator status, e.g: to put all the type of stops toghether.

Step 2. Enter the list in edinn

- Level: indicate the level of the status (see Statuses organization using levels)

- Code & Description: write a status code (e.g: STAT1) and a description (e.g: Quality test).

- Type: indicate the type below (step 1) defined.

Step 3. Save changes

- Press

to insert in the table the configuration of the status. Repeat this action for each status to add.

to insert in the table the configuration of the status. Repeat this action for each status to add. - When all the changes have been done, press the

button.

button.

NOTE: Please see Status configuration for deeper configuration.